Magnetic Receptive Graphics

Versatile Signage for Changing Needs

Hopkins Printing offers magnetic receptive graphics, a sleek and cost-efficient solution for businesses needing dynamic signage. Perfect for applications that require frequent updates, magnetic receptive graphics provide flexibility, affordability, and ease of use, making them ideal for retail, hospitality, and event promotions.

What does magnetic receptive mean?

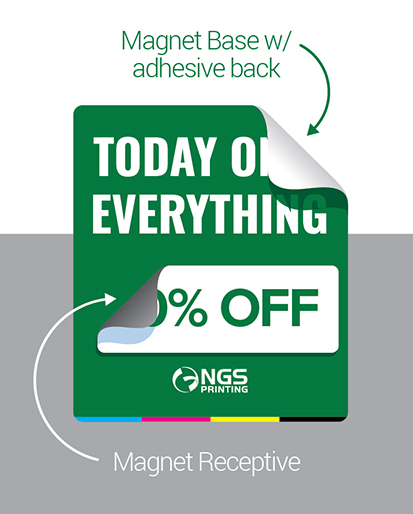

Magnetic receptive graphics and materials serve as a sleek, easy and cost-efficient solution for signage applications that change frequently. Lightweight and flexible, this form of signage has magnetic properties that enables it to stick to surfaces that aren’t exclusive to metal or steel. This is made possible through the use of pairing it with a separate adhesive-backed magnetic base. Using adhesive, the magnetic base is installed to nearly any flat surface to make it into a magnetic surface. Then, the magnetic receptive is what gets printed and changed. This fact alone provides added versatility so you can use magnetic receptive signage in many different places.

The printed magnetic receptive material is quite different from a simple magnet. It is extremely light weight, rollable and won’t stick to a refrigerator. Many of the advantages make magnetic receptive a much less expensive product when compared to a standard magnetic graphic.

Magnetic receptive graphics are used by many different businesses to further their sales, services and performance goals. Restaurateurs love them because they can update menus on an as-needed basis for new dishes or specials. They’re also great for point-of-purchase displays among retailers, whether high-end or big box. They can also advertise major sales promotions leading into the holiday season or some other event where prices on merchandise are cut.

Benefits of Magnetic Receptive Graphics:

- Versatility: Adheres to various surfaces, including plastics, smooth concrete, and even cardboard.

- Cost-Effective: Lower production and shipping costs compared to standard magnetic signs due to reduced iron content and lightweight design.

- Reusable: Double-sided printing allows for repeated use, saving money on follow-up campaigns or announcements.

- Easy Storage & Shipping: Ultra-thin and rollable for convenient storage and lower shipping costs.

- Dynamic Displays: Perfect for frequently updated content, such as menu specials, seasonal promotions, or rotating advertisements.

Applications for Magnetic Receptive Graphics:

- Point-of-Purchase Displays: Enhance retail spaces with flexible graphics that are easy to update.

- Restaurants: Update menus or daily specials quickly and affordably.

- Event Promotions: Advertise sales, holiday events, or temporary offers with minimal hassle.

- Retailers: Reduce long-term costs for recurring promotions or product highlights.

Magnetic Graphics vs. Magnetic Receptive Graphics

While both products share magnetic properties and are often used for similar purposes, key differences include:

- Surface Compatibility: Magnetic receptive graphics work on non-metal surfaces when paired with an adhesive base, unlike traditional magnetic graphics that require ferrous metal surfaces.

- Cost Savings: Magnetic receptive materials are more affordable for long-term use due to their reduced iron content and lightweight construction.

- Ease of Use: Magnetic receptive graphics are simple to apply, store, and replace, making them ideal for dynamic signage needs.

There’s a lot of magic to magnets and at Hopkins Printing, we know that our magnetic receptive materials can work for many of your signage needs. In addition to our attention to detail and customization, we have high-end equipment so the graphics and colors you select are bright and crisp. This is thanks to our G7 Master qualification, which we’ve earned for 10 straight years in color proofing from Idealliance, the International Digital Enterprise Alliance.

Why Choose Hopkins Printing?

For expertise that’s unparalleled and quality products you have to see to believe, turn to Hopkins Printing for all your signage needs. We bring graphics to life. Please contact us today online or come by and visit us here in Elgin, Illinois.