TYPES OF RETAIL SIGNAGE

Plastic is a reliable printing base for a variety of applications. Not all printers are capable of printing on plastic. Printing on plastic surfaces requires specially formulated inks, ink curing, and sometimes material topcoats for good ink adhesion. Companies that offer UV screen printing or flatbed digital inkjet printing are usually capable of printing on a variety of plastic materials.

Hopkins Printing is a leading supplier of printing on plastic services. Our innovative custom solutions can be used for a wide range of applications. From Personal Protection Equipment (PPE) to retail signage, to point of purchase graphics (POP), we’ll help you find a plastic sheet printing solution that meets your needs.

Our custom plastic screen printing services make printing on durable, long-lasting, high-quality base materials an easy process. Whatever signage you need for your company, we can help. Hopkins Printing is your source for large scale screen printing and digital printing onto an array of plastic materials.

Screen printing is a versatile, high-quality, and durable print method and the preferred solution for most plastic materials. Specially designed digital inkjet printers with inks formulated for curing on plastic surfaces are also increasingly common for signage and retail graphic purposes.

Here is what you can expect from our innovative printing on plastic services:

Our Plastic Screen Printing and Digital Printing Services

Early in the design stage of creating in-store marketing, there comes a point that a base material must be selected. The vast majority of all printed retail signage or point of purchase graphics are printed on either a plastic or paper-based material. Utilizing plastic as a base material can be extremely beneficial to customers in need of printing services.

Here are a few advantages of using plastic:

- Long Life Expectancy

Plastic as a printing base material has a much longer life expectancy compared to any paper-based product. Many plastics are built to hold up to the wear and tear that retail applications provide. This is especially useful for applications where the product may be touched or handled occasionally. Plastic is highly recommended instead of cardstock or cardboard if the signage is expected to be in the field for longer than a month. - Weather Resistant

Plastic offers efficient weather resistance. Certain printing bases like paper are highly sensitive to humidity, UV exposure, and moisture. Plastic providers unparalleled durability to a variety of weather elements. - Clear Printing

Plastic is one of the only materials that allows for printing on clear, transparent material. While glass is often the first consideration and thought, plastic is a much safer option for signage applications. Face shields, retail barriers for PPE uses need a durable, shatter-resistant, safe material that only plastic provides. Materials like PETG are shatter resistant and stronger than glass. - Style

When the look, design, and feel of a graphic is important, plastic is heavily preferred for a base material compared to paper and cardboard options. What many people don’t realize is that the design and construction of any sign directly reflect on the product or brand being sold. Attractive signage brings eyes and excitement, while damaged, poorly printed, or cheap signage may attract eyes for the wrong reason – which also reflects on the product being sold.

When elegance, professionalism, and quality is important, plastic should be your first choice. Plastic is very customizable because it can be bent, thermoformed, backlit, transparent, die-cut, router cut, or can be ordered as flexible or self-standing rigid without the need for reinforced flutes. Clear plastics offer an elegant look and can be printed 1st or 2nd surface with white ink. - Cost

At first glance, plastic looks to be the more expensive option. On the other hand, paper and other base materials have many hidden costs, such as laminates, extra mounting, and more frequent replacement costs. In the end, plastic will look more impressive and can prove to be less expensive in the long run. Plastic is an affordable solution for a variety of signage applications.

Applications of Plastic Sheet Printing

As stated, plastic sheet printing can be used for a variety of applications ranging from retail signage to vehicle advertising. Plastic signage is utilized across verticals for advertisements, educational purposes, decorative elements, and more.

Here are some of the most popular applications of plastics in print:

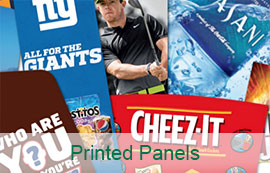

- Point of purchase displays – side panels for semi-permanent or permanent use, rigid headers, etc.

- Aisle marketing – shelf strips, shelf talkers, wobblers, aisle violators, etc.

- Retail signage – category signs, hanging posters, floor graphics, etc.

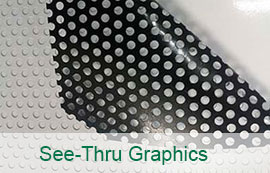

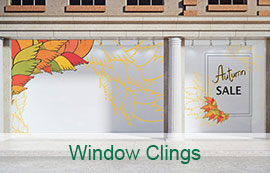

- Window graphics – stickers, static clings, perforated see-thru signage, die-cut decals, etc.

- Vehicle advertising – decals and magnets utilizing flexible plastic PVC

- Outdoor use – yard signs, campaign signage, banners, pole signs, etc.

- Floor graphics and concrete sidewalk signs

- Covers – membrane overlays, protective shields

- PPE – shatter-resistant face shields, face masks, etc.

Custom Plastic Screen Printing Materials

The materials utilized in the Hopkins Printing process are all high-quality products designed to last. Our various transparent plastic printing materials create innovative, unparalleled products for companies looking for streamlined printing solutions.

Hopkins commonly prints on clear materials such as thin gauge PVC vinyl, PETG, acrylic, polycarbonate, or PET using our screen and digital inkjet printing presses. Most designs on clear plastics need a white behind the image to increase contrast and opacity.

Here are a few of our commonly used materials that our team prints on:

Clear Materials

- Acrylic

- PETG

- Polycarbonate/Lexan

- PVC in thin gauges

- Polyester / Mylar

White or Colored Materials

- HIPS: High Impact Polystyrene

- PVC: Expanded PVC

- PVC: Flexible pressure-sensitive adhesive-backed vinyl

- PVC: Rigid PVC

- Polycarbonate/Lexan

- ABS

- Acrylic

- Polyethylene Fluted Polypropylene (aka Coroplast)

High-density polyethylene is an alternative printable material to polystyrene. It is generally less expensive, softer, and cuts easily. Polystyrene has superior printability and ink adhesion.

Your Custom Plastic Screen Printing Partner

At Hopkins Printing, we have invested in large format UV screen printing and large format UV digital printing. We specialize in printing on either paper or plastic-based sheets.

For over six decades, Hopkins Printing has been printing on rigid plastics, and we have the capability to print white ink, spot colors, or four-color process images to suit your next project. Our dedicated experts are here to help you with any questions you may have concerning the plastic printing process or if you need help deciding which is best for you.

Discuss your project with an Account Executive here to uncover the best material for your application. Reach out to our team of experts today!